What are the differences between waterjet cutting and plasma cutting, and which one is better? Find out everything you need to know here.

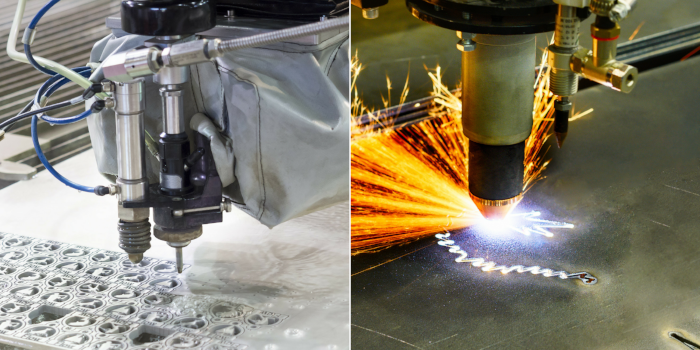

Plasma cutting, also known as plasma arc cutting, is a process in which a jet of ionised gas at temperatures above 20,000⁰ C is used to melt material. During the process, a stream of gas is blown at high speed while an electrical arc is passed through it. This causes some of the gas to become very hot plasma. The gas is moving fast enough that the molten metal is blown away from the cutting area.

Plasma can cut a wide range of electrically conductive alloys including plain carbon and stainless steel, aluminium and its alloys, titanium and more.

With plasma, the edge quality is similar to that achieved with the oxy-fuel process. However, as the plasma cuts by melting, this results in a top edge rounding, poor edge squareness or a bevel on the cut edge.

Advantages of plasma cutting:

- Can produce part accuracies better than 0.008”

- Can process 16-gauge mild steel at over 200 IPM and 1” thick mild steel at over 45 IPM

- Recent advances in technology have greatly improved quality

- Can be carried out under water with specialised equipment

Advantages of waterjet over plasma cutting include:

- Operation at much lower temperatures and no heat affected zone

- Can cut materials that don’t easily melt, such as granite

- Can cut materials that are destroyed by melting (many laminates)

- Higher level of precision and accuracy

- The edge quality on plasma cut stainless steel is not as acceptable in some markets as waterjet processed parts

- More environmentally friendly, as plasma cutting produces fumes from the cutting process

While each profile cutting technique tends to be more suitable for one application than another, making it hard to compare methods; when juxtaposed with plasma, waterjet cutting undeniably takes the lead in relation to quality, accuracy, and cost efficiency.

Find out everything you need to know about waterjet cutting in order to effectively establish whether it’s the most suitable method for your needs with our free eBook, ‘An engineer’s guide to waterjet cutting’. In the eBook you can also see the method compared to four other profile cutting techniques.