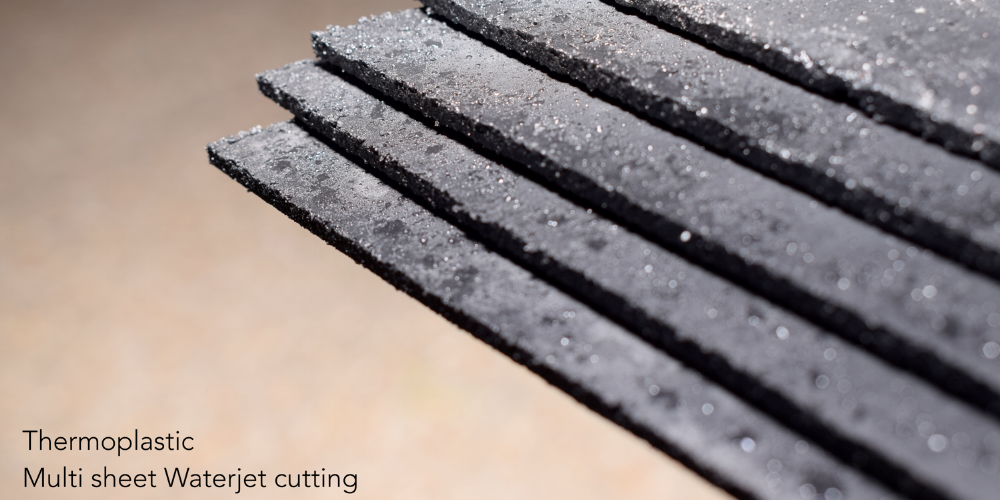

A thermoplastic is a plastic material that becomes mouldable above a certain temperature and solidifies upon cooling. Certain types of thermoplastic can be tricky to profile as they can crack when being cut, therefore, more care must be taken when working with this...