Advanced Design Capability

Your concept, brought to life.

ICEE’s Design for Manufacture service is powered by our in-house, highly qualified design team. With seven dedicated design technicians, they have extensive experience in bringing your vision to life, whether it’s a telecommunication, fibre, power or other enclosure. Utilising the latest technology from SolidWorks, we have a range of capabilities.

Our Design for Manufacture service can be utilised as a singular, stand-alone service, or as part of a turn-key design and fabrication process. Either way, our team will cater to your exact project needs and requirements. To find out more, please phone us on 02392 230604 or email sales@icee.co.uk

What’s the benefits?

Choosing ICEE to design your product has a whole range of benefits. From industry experts with years of experience, to advanced software capabilites, our Design for Manufacture service is a great option for all industries.

Quality Assurance

ICEE are ISO 9001:2015, JOSCAR and RISQS registered. This ensures we up-hold the highest quality. Learn more about our accreditations.

Years of Experience

From dynamic motorways, through to hydrogen refuelling, our designers have worked on a range of products throughout the years.

One Service Provider

ICEE’s turn-key offering is one of the reasons customers keep coming back. By having your project designed and manufactured in house, we have full traceability of your products.

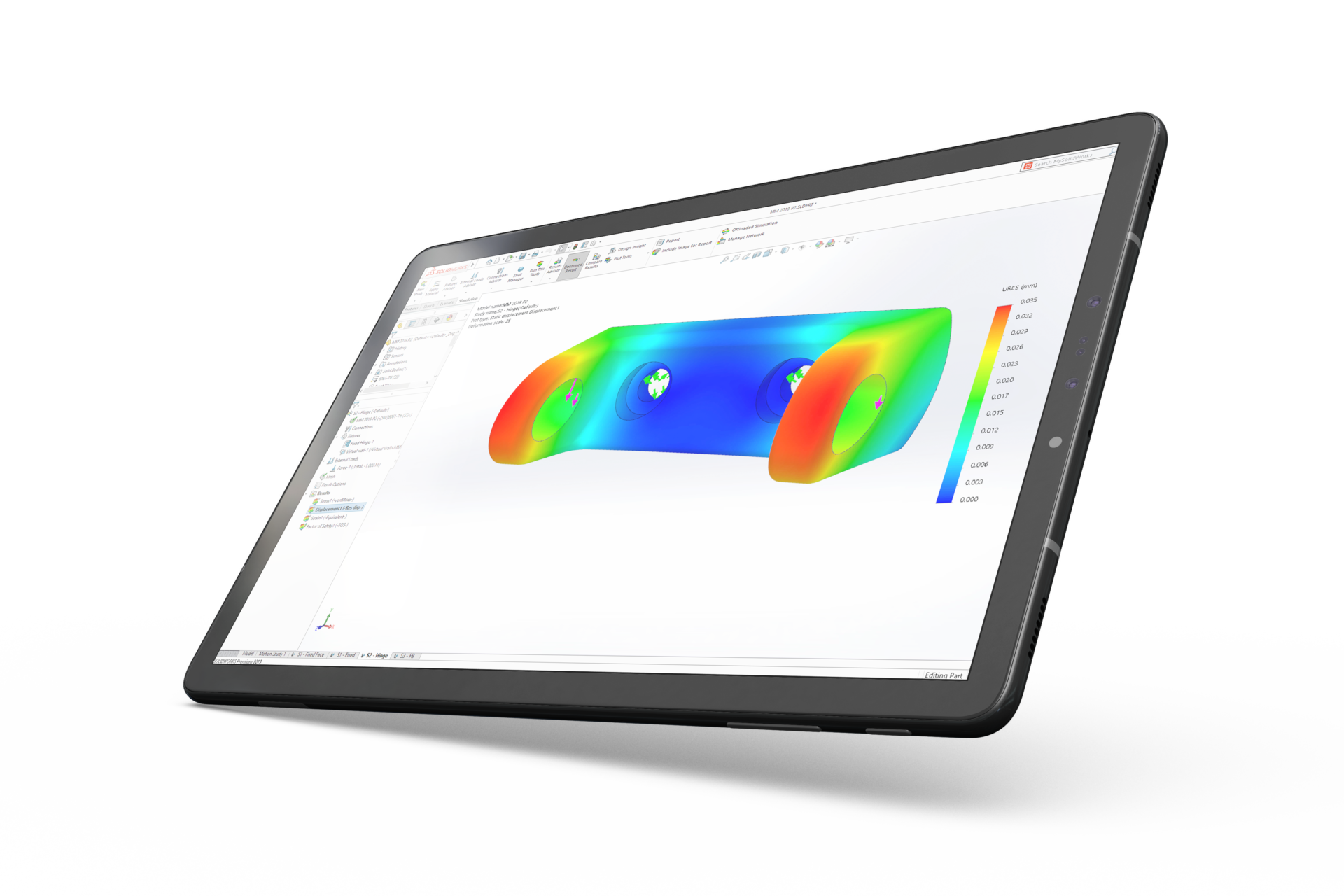

FEA Testing

Alongside our Design for Manufacture Service, our Design Team can perform FEA Testing of products and prototypes, allowing customers to have a better understanding around their product’s reliability and load capacities.

FEA Testing

Simulation testing, for the harshest environment.

Finite Element Analysis (FEA) is the simulation of any given physical phenomenon using the numerical technique called the Finite Element Method (FEM). We use FEA Software to reduce the number of physical prototypes and experiments, while optimizing components in their design phase, developing better products faster while saving on expenses.

FEA allows customers to establish real-world scenarios for a wide range of parameters such as durability, static and dynamic response, motion of assembly, heat transfer, fluid dynamics and plastic injection. To find out more, please phone us on 02392 230604 or email sales@icee.co.uk

What can it test?

Understanding key design and safety features is paramount when designing a product. Our FEA Service allows customers to learn about the strength of fixings within a product, the amount of load it can hold, and predict its life in use.

Fixings & Bolts – Understanding the safety and manufacture of how your product is assembled can be crucial to knowing the capabilities and risks when it comes to actual practice. Using our FEA Simulations, our Design Team can test the structural integrity of bolts and fixings within the product, measuring them against the factor of safety (FOS).

Fatigue Testing – Fatigue is the gradual and localized structural damage that occurs when a structure is subjected to cyclic loading. There are many factors which can affect the fatigue life of a product, including the loading type (thermal, vibration etc) surface finish and surface treatment.

All aspects of our FEA Testing Service can be purchased as a one-off, or as part of our turn-key manufacturing process.