ICEE Managed Services, based in Waterlooville, Hampshire, are a leading manufacturer of bespoke metal enclosures, within a range of industries. Alongside this service, they also offer independent metal manufacturing services, such as welding, folding, profile cutting and more. However, using their highly qualified in-house design team, they now offer FEA Testing and Simulation services, as a bolt on to their turn-key solution, or as a standalone product. Barry Croft, ICEE’s Head of Design, explains the new service, and the use cases it could have for sheet metal manufactures across the United Kingdom, and the wider globe:

“Finite Element Analysis (FEA) is the simulation of any given physical phenomenon using the numerical technique called the Finite Element Method (FEM). At ICEE, we use FEA software to dramatically reduce the number of physical prototypes and experiments, while optimizing components in their design phase, allowing us to innovate and design new products faster, while saving customers money. The highly innovative software, which is made simple by our in-house design team, allows us to test for a range of scenarios, such as durability, heat transfer, weight testing and more.

Within our business, the service has been of particular interest to our Bespoke Enclosure Customers. Commonly, when embarking on a new project and design, we encourage customers to opt for the new service, for reasons of both design and compliance. By undertaking the FEA Testing earlier in the manufacturing process, it allows us to instantly spot areas that may have issues and rectify the issue quicker”.

ICEE have rolled out the software across their in-house design team and have been using the software on a variety of prototypes, as well as products which are further into their manufacturing process. One area that ICEE have seen particular uptake and requests for the service to be used, is for customers who are having different bracketry made for them. Shane Thomas, a key account manager at ICEE, explains how the system works in these instances:

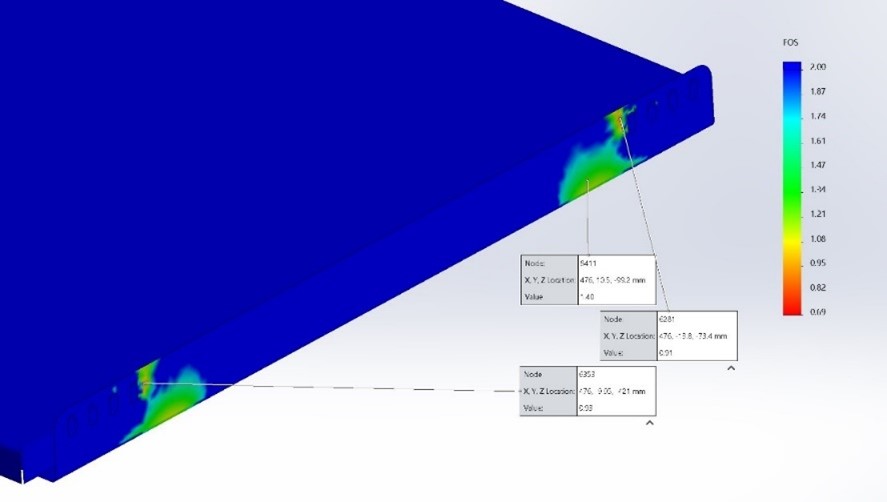

“As customers request further testing and information regarding their products safety and service life, FEA testing could not come at a better time. When using the software on bracketry prototypes, we can test the fixings & bolts that will attach the bracket, the maximum load bearing on the bracket, and the lifespan of the product, using fatigue testing. If you look at the photo on the right, you can see how the software has allowed us to see that this particular bracket, would not be able to hold

the required weight needed. The green indicates that over time, the area around the bolts and fixings, would begin to fatigue. To counter this, we communicated with the customer, and informed them that the thickness of metal they were trying to use, in this case 2mm Stainless Steel, would not be fit for purpose. Instead, we opted to use 3mm, which ensured the bracketry of the shelf, met all requirements.”

The capabilities of the service offered by ICEE stretch far and wide. If you are looking for a service like this or are in need of some extra satisfaction your product can withstand its high expectations, ICEE can complete FEA testing based on already existing drawings and models, or from complete scratch. To find out more about the new service, visit the dedicated page below: