Metal Fabrication Services

At ICEE, we offer a range of different manufacturing techniques, working with a vast variety of industries. Aside from sheet and metal cutting processes, we offer bending, welding, plating, coating and final product assembly. This makes our Metal Fabrication service.

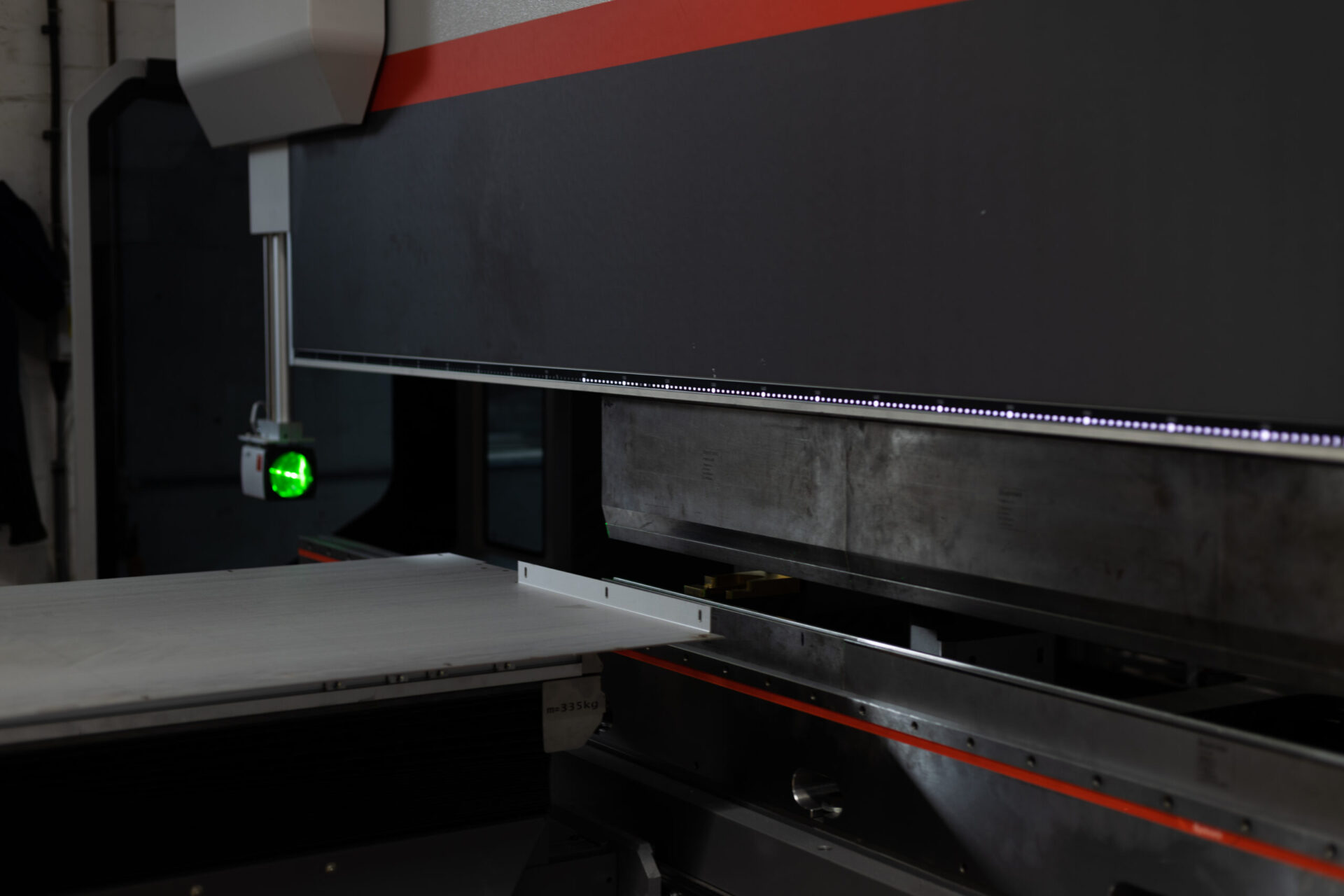

Metal Bending

Metal bending can be a complex process, but not for our state of the art CNC press brake machines. We offer our clients dramatically reduced set-up and lead times.

Welding Services

Our fully equipped and modern welding shop, enables us to construct small to medium size fabrications in carbon steel, stainless steel and aluminium.

Metal Plating

Metal plating is a necessary process that provides many benefits, including improved corrosion resistance, increased solder-ability, and many others.

Coating and Finishing

We know how important it is when investing in valuable assets to ensure that they are protected from damage and their life-span maximised.

Assembly

As a managed service, we can expertly assemble, test, warehouse and deliver your products. Our product assembly is flexible, to ensure it suits your needs.

Benefits

Choosing ICEE offers you a range of benefits, including one point of contact, rapid testing, flexibility and access to the latest technology.

Metal Bending

Metal bending can be a complex process, but not for our state of the art CNC Brake Press machines. From small and simple, to giant four-metre folds on plate material, ICEE offers its clients high quality bending that delivers exceptional precision, reliability and productivity, with dramatically reduced set-up and lead times.

Our Metal Bending Services

Our metal bending service is available as a single process, in combination with other fabrication services, or as part of a total end-to-end fabrication package, meaning that we can virtually manufacture any metal enclosure or product you want, as well as provide you with all the subsequent services, including installation, commissioning, maintenance and more.

Welding

Services

What we offer:

Our fully equipped and modern welding shop, enables us to construct small to medium size fabrications in carbon steel, stainless steel and aluminium. While the majority of our work has previously revolved around sheet metal and plate material, we are certainly not restricted by them, and we will also undertake demanding sub-contracted projects that require special resources.

A Range of Welding Packages

Welding is available as a stand-alone service, in combination with other fabrication services, or as part of a total end-to-end manufacturing package, which offers significant cost saving benefits to our clients. The service is also available as part of our bespoke enclosures solution.

Highly Qualified Experts

We pride ourselves with exceptional quality assurance and compliance. We strictly adhere to the British Standard Specifications and other recognised codes including Class 1 Coded Welding to BS EN 287-1 2011. Whats more, ICEE has been awarded safe contractor status and achieved stringent ISO 9001:2008 quality management accreditation.

Our Welding Methods

Our range of welding services includes conventional gas welding, metal insert gas (MIG) welding, tungsten inert gas (TIG) welding and spot welding, along with coded welding or specific applications, performed by highly skilled and qualified operators. We have the ability to weld a wide range of materials – from carbon and stainless steel to aluminium processing.

Metal Inert Gas (MIG)

MIG uses heat generated by a DC electric arc to fuse metal in the joint area. The benefits of the method include:

- Extremely versatile process that can weld a variety of metals and alloys

- Offers quicker turn-around time times, due to the higher productivity of the method and its simplicity

- The method makes it easy to produce neat weld runs

Tungsten Inert Gas Welding (TIG)

TIG welding is an arc welding process that uses non-consumable tungsten electrode to produce the weld. The benefits of the method include:

- Production of high-quality and low-distortion welds.

- Ability to weld almost all metals and metal alloys in use today, including dissimilar ones

- Gives precise control of welding heat, therefore delivering better quality of weld.

Spot Welding

Spot welding is the welding of overlapping pieces of metals at small points by application of pressure and electric current. The benefits of this method include:

- Fast and easy process that offers quick turnaround times on a low cost

- Has the ability to weld very thin sheets of metal

- Possible distortion or warping of parts is eliminated.

Plating, Coating and Finishing

We know how important it is when investing in valuable assets to ensure that they are protected from damage and their life-span maximised. This is why, here at ICEE, we use the best plating, coating and finishing resources to ensure extreme durability of our products and bring peace of mind to our clients about the safety and longevity of what we supply.

Providing high quality service is of utmost priority to our team, which is why we wanted to establish a fine balance between having some of our plating and coating processes completed in-house and, as appropriate, some performed by high-quality external contractors. In-house or external, we apply the strictest controls and testing to ensure that the customer’s specification is met fully and that the end product is safe, protected, and of high-quality.

We have the ability to process small parts and large assemblies, one-off or in high volume, including on-site work at the customer’s location. Our wide range of metal finishing includes:

- Hot dip galvanising

- Cold galvanic coating

- Electro-plating

- Painting

- Powder coating

- Chroming

- Zinc plating

Metal plating is a necessary process that provides many benefits, including things such as improved corrosion resistance, increased solderability, enhanced strength, reduced friction, altered conductivity, increased magnetism and more.

Product Assembly

Here at ICEE, as a managed service, we can expertly assemble, test, warehouse, and deliver your products. Our product assembly service is completely flexible and designed to meet your specific needs. We have the capability to assemble products at our premises from free-issues parts you supply us with, or with our own products, fabricated onsite. Based on your specification and supply chain requirements, our experienced in-house purchasing team will also procure and stock any necessary bought-out component parts or equipment.

Our Assembly Capabilities

Our expert engineers are able to assemble everything from:

- Panel wiring

- Cable assemblies and wiring looms

- Electrical and mechanical assembly

- Power distribution unit assembly

- Highways MCX boxes

- 19” and Etsi Rack builds/furniture

- AC/DC circuitry

- As well as provide you with: NICEIC Test and accreditations; Factory Acceptance Testing (FAT); Logistics; Warehouse management; Delivery

Benefits of using ICEE:

- Scale of capabilities – from small engineering parts to large structures for the construction industry. Applying up to 150 tons of pressure on long folds, the bed of our largest brake press will accept up to 4-metre workpieces.

- Design optimisation – we work closely with customers to optimise the design of folded components, aiming to enhance functional performance, and minimise cost.

- Knowledge and experience – our qualified design team and highly experienced press brake operators guarantee accuracy, efficiency, and fast delivery of the production process.

- Range of materials – we fold both ferrous metals including stainless steel, mild steel, Zintec and most non-ferrous materials, such as aluminium, copper, brass and more.

- Flexibility – CNC-based, our machinery set-up and tooling is flexible enough to accommodate any requirements, whether simple or complex. We can provide one-off, batch or volume production.

- Rapid testing – products will be rapidly tested and submitted to stringent quality controls. We test all prototypes in-house and there is a constant conversation between our design and engineering departments, which means that any issues are quickly resolved and the necessary changes made.

- Cost-efficient – our in-house resources and lean manufacturing mean that low volumes of products also mean low price, while at the same time meeting bespoke demands.

- Access to the latest technology – we always invest in the latest technology, which means that our clients have access to state of the art production machinery and test equipment that deliver the highest possible standard of service.