Aluminium and its alloys are versatile, attractive, durable and very strong for their weight, which makes them the preferred material for a lot of applications.

While there are many different machining methods to cut aluminium, such as laser cutting, plasma cutting, hacksaws and even shears for cutting very thin aluminium sheets, probably the most convenient, effective and versatile methods of all is waterjet cutting.

Some of the many advantages of cutting aluminium with a waterjet cutter include:

Waterjet can cut up to 20 cm of thickness

Waterjet can cut up to 20 cm of thickness- Thin sheets, including 6061 alloy aluminium, can be stacked for cutting

- There is no secondary finish

- There is no melting during the process and no burr finish left

- Very intricate designs and patterns can be used to cut the material, delivered with a very smooth finish

- There is no material deformation

- No hardening of the material along the cut edge

- No heat affected zone (HAZ)

- None or minimal need for reworking

Examples of aluminium cut with a waterjet:

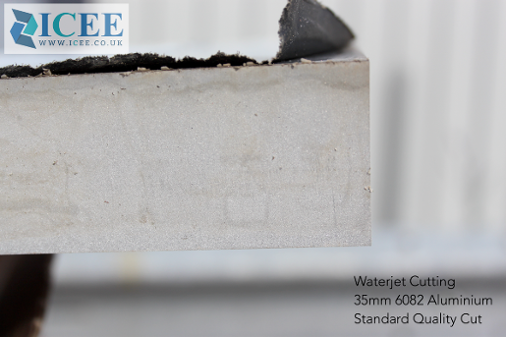

35 mm 6082 Aluminium

- Quality cut

- Speed – 77 mm per min feed rate

- Piercing time – 8 seconds

- Quantity of abrasive (garnet) used whist cutting equals 400 grams per minute

100 mm 6082 Aluminium:

Quality cut

Quality cut- Speed 21.7 mm per minute feed rate

- Piercing time – 53 seconds

- Quantity of abrasive (garnet) used whilst cutting 400 grams per minute

Find out everything you need to know about waterjet cutting with our hands-on and free to download: ‘An engineer’s guide to waterjet cutting‘ eBook.